Various types of axes include felling axes, splitting axes, hatchets, tomahawks, carpenter’s axes, forest axes, adzes, and double-bit axes. Each type serves specific purposes, such as cutting down trees, splitting wood, carving, combat, and woodworking, showcasing their versatility across diverse applications.

There are many types of axes and axe heads. They each have their own design, purpose, and history. While it would be almost impossible to write about all of them, this is a guide to the most common and popular types of axes out there. This list contains both different types of axe and axehead designs.

So without further ado, lets get into it!

Table of Contents

1. Cutter Mattock

A cutter mattock can be considered a type of axe. That is because it has an axe blade on one side and the adze blade on the other. Cutter mattocks are excellent for clearing trails and making clearings in areas thick with roots in stony ground. The adze side can be used to dig, leverage and pull rocks and rip up roots, while the axe side can either cut through roots or chop through fallen or standing wood. A pick mattock doesn’t have an axe edge – it has a pick on one side of the head and an adze on the other.

2. Hudson Bay Axe

Hudson Bay axes have an axehead that has a teardrop-shaped eye, a flat poll, which weighs around 2 lbs and which is usually mounted on a 20”-28” handle. The name comes from the Hudson Bay Company, which dominated the fur trade in the Hudson Bay area and its drainage basin (that is, the rivers flowing into it) in modern-day northern Canada and some parts of the northern US. In the image above you can see that the toe (top tip) of the axehead is barely above the level of the eye, while the heel (bottom tip) of the edge is swept down and back slightly.

Hudson Bay axehead pattern axes were popular with fur traders, woodsmen, and canoe people. They were not meant to be used as felling axes, instead they were all-purpose camp axes good for limbing tree branches and cutting down small trees to use for building shelters, processing firewood, hunted-down big game and so on. Users adapted the handle length to their needs – Hudson Bay pattern axeheads were mounted on both large and small handles, although the most popular sizes were the above-mentioned 20 to 28-inch handles.

Hudson Bay axes were handier and more useful than hatchets, but lighter than big felling axes. Their flat polls allowed the user to drive wooden stakes with them or use them as a hammer if necessary. French “trade axes” that traders sold to Native Americans in exchange for beaver pelts had no poll (the steel wrapped around the handle) and were usually of lower-quality steel, so the superior Hudson Bay axes became desirable tools for Native Americans and gained popularity among European settles not long after, as well.

My recommendation for a Hudson Bay axe is the Council Tool model pictured below. It is made in USA with a curved 18 inch hickory handle.

3. Double Bit Axe

Double bit axes have two bits, or cutting edges, on the axehead. These are mounted on both smaller and larger handles, and have two main benefits. The first is that you don’t have to sharpen the edges as often (since there are two). If you’re felling many trees and one edge starts getting dull, you can simply flip the axe around and start using the second edge.

The second benefit is the ability to use one side for “clean” work, such as only chopping trunks and branches, and the other side for “dirty” work that dulls the axehead faster or that brings greater risk of damage – such as chopping up roots or splitting wood on the ground. Therefore, even if one edge does get dull or damaged, you still have a sharp, fit-for-work second edge. This makes the double bit axehead heavier, of course, but that is also not always a bad thing, especially when felling trees.

Have a read through the guide I put together comparing double bit axes. The #1 double bit axe on that list is the Estwing model. It is made in the USA in Rockford, IL, from forged steel and comes with a ballistic nylon sheath.

4. Felling Axe

Felling axes are one of the main types of axes out there. These are large axes, with handles ranging from 30 to 36 inches and axe heads weighing starting from 3 lbs and going up to 5 and even 6 pounds. These axes need to be hefty and with long handles so that the user can put a lot of force into his (or her) swing.

If you’re interested in buying a felling axe, I’ve written a guide to the best felling axes on the market.

Felling axes also usually have wide, slightly curved bits that provide a longer cutting edge and allow the axe to dig deep into the wood and take big bites out of it. Axes meant exclusively for felling also tend to have a more concave shape (also referred to as having thinner cheeks) so that the bit can penetrate deeper and more easily into the wood. Felling axehead patterns that are also used to split wood – such as the Michigan axe pattern – would have slightly more concave shapes (or fatter cheeks).

Finally, felling axes in the New World – the United States and Canada – were and are larger and heavier than axes used for felling in Europe, as hardwoods such as maple, oak, hickory and Douglas fir (officially a softwood, but harder than some hardwoods) and others were and are more widespread in North America (including Mexico) than in Europe, where softwood species such as pine and European firs dominated in forestry.

The axe pictured below is the Hults Bruk Medium sized felling axe. It is 2.8 pounds with a head made from Solid Swedish Steel and a handle from solid American Hickory.

5. Dayton Axe

Dayton pattern axeheads are named after Dayton, Ohio. These are full-sized felling axes that were (and maybe still are) used to fell hardwood trees that you would build your home out of. Unlike Hudson Bay axeheads, with their 2-pound weight, Dayton axeheads usually weigh starting from 3.5 lbs and going up to 5 pounds.

6. Michigan Axe

The Michigan axe head pattern appeared in the 1860’s in Michigan, where settlers logged big eastern white pine (pinus strobus) trees. The Michigan axe pattern is similar to the Dayton pattern, but with a more rounded poll end and thicker (or fatter) cheeks that made it suitable to use as a splitting axe in addition to felling. Put in terms of geometry, a Michigan axe has a more convex shape as opposed to the Dayton axe’s more concave form.

Michigan axes had wide bits (good for biting deeper into wood) and the toe and heel or top and bottom tips of the edge were slightly rounded, which helped prevent the cutting edge from chipping when swung into the often frozen and just as often knotty pine wood widespread in Michigan.

7. Jersey Axe

Jersey axes have what is known as a “lug”. This is an extension of the axehead’s cheek facing downwards at an obtuse angle. This gives more contact between the axehead and the handle and improves stability. The Jersey axe’s toe, heel, and poll corners are also more angular than the rounded Michigan axe. The Jersey axe pattern, just like the Michigan pattern, is still popular nowadays in modern axes, which says something about its effectiveness. Jersey pattern axes also often had bevels forged or grinded into the cheeks to reduce friction and the axe getting stuck in wood when bucking (cutting up into sections) felled trees or splitting wood.

In the photo below is the Council Tool Jersey Axe. The forged tool steel head is made in USA and is hand sharpened with a 36 inch hickory handle.

8. Swamper’s Axe

Swamper’s axes were used by swampers – the men who limbed a tree after it had been felled and then cut it up into sections to make transportable logs. Swampers cleared brush before fellers got to work and made logging roads and trails in the forests. Swamper’s axes were meant for limbing and bucking a tree, and working fast was important. That’s why the bits on swamper’s axes were wider and more rounded than on similar-sized felling axes – to buck trees into logs as fast as possible and reduce the risk of chipping or breakage in case they did hit a nasty knot or if they were working with frozen wood.

9. Forest Axe

Forest axes, sometimes known as woodsman’s axes, are all-purpose axes meant to be taken on trips – however long – into the forest. They are often large enough to fell and limb trees, but usually not as large as true felling axes. This is because portability is important for a woodsman walking for several miles or days, with other survival essentials, supplies, and tools in his pack. Forest axes are often similarly sized to boy’s axes – that is, with a handle that is 24” to 28 inches.

10. Pulaski Axe

A pulaski axe, sometimes also called a fireman’s axe is designed for fighting fires. It was designed in 1911 by a man named Ed Pulaski, originally for use by the United States Forest Service. He added an adze edge to the poll side of the axehead, so that forest rangers and firefighters battling against forest fires could use the axe to dig up lines of earth to block a fire from spreading, as well as to use as a rescue tool in case anyone was trapped under debris or earth. It became very popular for fighting forest fires.

Fireman’s axes are similar in design, but instead of an adze edge have a pick on the poll side. This is for breaking through doors and walls, as well as for moving debris. It works better for breaking through obstacles as all the force of the swing is concentrated in the narrow tip of the pick, instead of distributed along the edge of the axe.

Check out my roundup of the best pulaski axes by clicking here. The top axe on my list is the Council Tool Pulaski axe – it is a large, serious tool that packs a punch with a 4 1/2 inch cutting edge, made from high-quality US steel.

11. Boy’s Axe

Boy’s axes are mid-sized axes also referred to as “cruisers”. Despite the name, boy’s axes are an excellent all-round axe for any age and in fact are suitable for most men, especially if you’re not looking to fell large hardwoods. Boy’s axes are usually made up of a 2 to 2.5 lbs axehead on a 24” to 28” handle.

12. Carpenter’s Axe

Carpenter’s axes are small axes – the size of hatchet or slightly large – that are specially designed for woodworking, joinery, and building with wood and logs. They often have a prominent beard and a finger notch to allow the user to wield choke up their grip and wield it with precise control. That way, a carpenter’s axe can be used for carving and lopping off ends of thick wooden beams if necessary. Proper carpenter’s axes also have hardened polls that allow the poll side to be used as a hammer.

I’ve reviewed the best carpenter’s axes and roofing hatchets here. My recommendation for a carpenter’s axe is the Estwing 13″ Hatchet. It is ideal for building, demolition, and woodworking.

13. Shingling Hatchet

A shingling hatchet or roofing axe is a small, straight-handled axe used by carpenters and builders. Its main features are that the poll is hardened to work as a hammer, and many models have a notch at the bottom of the axehead to use as a nail puller.

14. Hewing Axe

Hewing axes – also called broadaxes – are unique in that they are single-bevel axes – that is, only one side on the edge actually makes a cut. This makes them perfect for hewing logs into square beams, and that is how it was done in olden times before the invention of mechanized saw. Some hewing axes are double-bevel – they can be used for chopping and making notches at regular intervals along the log – this process is called scoring, and makes the wood easier to remove later, which is called joggling.

15. Crash Axe

Crash axes are specially-designed emergency axes for use in dangerous situations – such as crashes. Many US airplane crews were issued with crash axes, and even now an FAA regulation states that “each airplane accommodating more than 19 passengers must be equipped with a crash axe.” These axes were meant to be used as firefighting devices first and foremost – to break through and remove panels in the cockpit or elsewhere in cash of electrical fire. In cases of crashes, of course, these axes could be used to break through windows, stuck doors, and so on. Crash axes have been adopted for the mass market as well, often combining several functions into one axe, such as a crowbar, glass breaker, seatbelt cutter, nail claw, and even hex sockets in some.

16. Adze

An adze is an ancient cutting tool that was used for two reasons. The first was to smooth and carve wood in woodworking, and the second was to clear rocky or root-filled earth or till existing agricultural land for planting. It isn’t a proper axe, but it is similar, with the main difference being that the cutting edge is perpendicular to the handle (or, put another way, the edge is horizontal, not vertical like an axe) and was often used together with axes especially during woodworking. An adze, with a curved edge, was often used to “scoop” wood out of tree trunks when making canoes and was used to make other vessels such as bowls as well.

17. Tactical Axe

Modern tactical axes can be traced back to Vietnam tomahawks, which were issued to US troops as close-quarters, last-ditch melee weapons. They saw some use during that war, including among special ops units, who would use them for quick and devastating, but silent takedowns. The original Vietnam tomahawks were a dark green color, which was well-suited to the jungles of Southeast Asia, but modern versions are, more often than not, all-black.

The distinguishing feature of a tactical axe is that it has a spike on the poll end, allowing for either blows that penetrate deeper in a more narrow area – good for getting through layers of clothes – or more traditional axe cutting attacks, suitable for lightly covered or uncovered parts of the body. Be careful when using such a design! Get used to the spike being there on the poll end, otherwise you might hurt yourself or someone near you with a careless or misjudged motion.

18. Viking Axe

Viking axes have two main designs: there is the “skeggox” or bearded axe, and the Danish axe, which is known for its long, curved cutting edge. The first is based on the design of a typical everyday axe used by Viking men in their daily life, while the second is a battle axe made especially for raiding and war. Axes were one of the most common weapons used by Vikings, along with spears, as swords were rare due to how expensive and difficult it was to produce the amount of metal needed for swords. Here is my guide to viking axes – the best you can get on the market nowadays.

19. Throwing Axe

Throwing axes are meant for throwing – for hunting and wars in the past, as well as for fun and competitions in the past and present. Good throwing axes are characterized by simple design – tomahawks and other light axes were historically used as throwing axes and still are. A straight handle and light head with a relatively narrow cutting edge – for better kinetic concentration and penetrating force – are the optimum design. There are two organizations that have specific criteria for throwing axes used in axe throwing competitions. I’ve written all about those criteria and throwing axes here.

20. Tomahawk

Tomahawks were light, small axes used by Native Americans in their conflicts between themselves and against British, French, and other colonizers. Before the arrival of Europeans, tomahawk heads were made of stone and were secured with strips of rawhide to the handle. Europeans introduced metal and smithing to the Native American tribes, and often used metal tomahawks as diplomatic gifts or for trade.

21. Splitting Maul

Splitting mauls are not exactly axes, since they can’t cut anything. Instead, they are meant only for splitting logs or rounds of wood. The edges of traditional splitting mauls are quite rounded and the cheeks are fatter in a convex shape – the better to force apart wood fibers. Splitting mauls don’t really cut – they are heavy and use that weight and the force of the swing to literally force wood apart. Mauls are usually big and heavy, as splitting wood demands a lot of force. Mauls are often used together with splitting wedges, and many mauls have hardened polls that allow the user to hammer wedges into the wood with them.

22. Splitting Axe

Splitting axes are, as a rule, lighter and less blunt than splitting mauls. These axes, though, are made for the same purpose – splitting wood. Whereas many mauls have hardened polls that allow them to be used as hammers, not many splitting axes have this feature and they rely more on the design and power of the bit to split wood. Check out our guide to the best splitting axes.

23. Miner’s Axe

Miner’s axes refer to 2 to 2.5 lbs axeheads mounted on relatively short handles that allowed users working in cramped conditions – mines, for example – to process wood and do precision work by choking up on the handle just beneath the axehead, but also to apply more serious force if necessary. “Miner’s axe” can also refer to ceremonial axes carried by miners in Germany and other places in Europe since the Middle Ages that grew out of an axe design with a very narrow bit used in mines for prospecting and chiselling out veins of valuable silver, copper, and other types of ore.

24. Shepherd’s Axe

A shepherd’s axe is a type of axe that you don’t see much anymore. Known as a valaška in Slovak and Czech, a fokos in Hungarian, or a ciupaga in Polish, it was a tool used by European shepherds on the job. It had a long, straight shaft and the small axehead also doubled as the handle when used as a walking stick. When wolves, bears, and wild or rabid dogs and other animals (including humans!) threatened either the shepherd or his flock, he could and would use the shepherd’s axe to fight off the threat.

Shepherd’s axes could also be used as walking sticks on treacherous paths, as an axe to cut down saplings and remove branches for shelter-building, and other light tasks the shepherd might have to undertake while taking care of his flock.

Axe Parts and Terms

Axe head – the steel head of the axe

Eye – the hole that the handle or shaft is fitted into

Poll – the back side of the axehead

Bit – the area leading up to and including the cutting edge of the axe

Toe of the bit – the top tip of the axe bit

Heel – the bottom tip of the axe bit

Beard – the bottom curve of the axe bit. Beards can be long (as with many Viking axes), shallow, or in between.

Cheeks – the sides of the axehead, can be convex (wide) or concave (narrow) shape

Lug – where the axehead cheeks dip down at an obtuse angle over the handle. Gives more axehead-handle contact and makes the fit more durable.

Shoulder – the part of the handle where the wood “dips down” and becomes more narrow.

Belly – the side of the handle facing forwards.

Haft – the back side of the handle.

Knob – the very bottom of the handle.

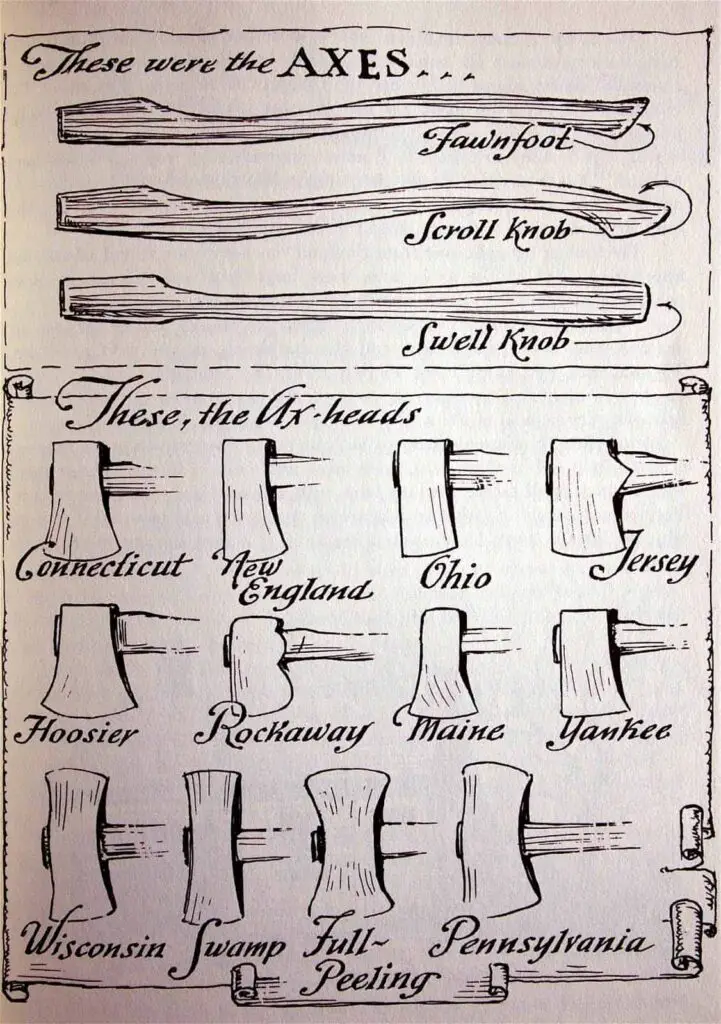

Knobs generally had three types:

- Fawnfoot knobs

- Scroll knobs

- Swell knobs

I have also written an article explaining these parts of an axe in more detail.

That’s all for now. Thanks for reading!