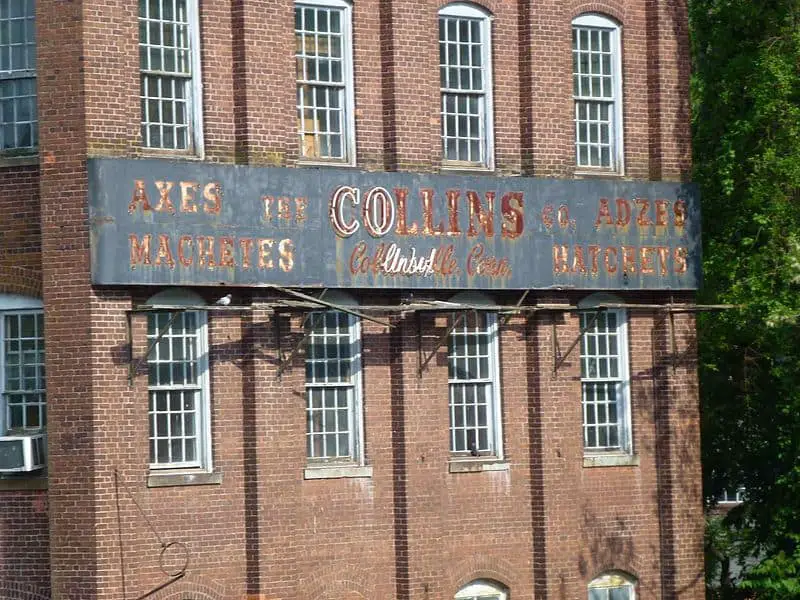

Collins Axe Company, founded by Samuel W. Collins in 1826, was a renowned American manufacturer of axes, machetes, and other edged tools. Known for its high-quality products, the company operated in Collinsville, Connecticut, and played a significant role in the development of the American axe industry.

Collins axes and other tools are immortalized in literature, stories told by everyday users, and in the tools themselves that have been passed down through the generations. This article is an in-depth look at Collins axes, the history of the Collins Company, a review of Collins axes available nowadays, and how to identify vintage models. Let’s get into it without any further ado.

Table of Contents

Collins Axe History

Collins axe history starts with Samuel Watkinson Collins, who was born in 1802 in Middletown, Connecticut, and founded the Collins Company in 1826 at the young age of 24. He started with making axes – a tool that every pioneer, logger, and builder needed at that time. It was also a time when ready-to-use axes – forged, polished, and handled – were not as widespread as nowadays.

Instead, people would go to smiths and order an axehead. Then they would either sharpen them to a fine edge and make and fit handles themselves, or find someone else to do it. The quality of smiths varied widely and buyers often had to hire whoever was available in their area or further afield due to waiting times. Collins’ winning idea was to produce standardized, well-made axes on a large scale. To do that, he and his brother bought a gristmill with a water wheel on Farmington River near Canton, Connecticut. They then got to work.

Word of these fine, ready-made axes spread quickly and demand soared. Collins upgraded his equipment and soon, each smith in his employ was turning out 10 axeheads a day. In 1831, just five years after starting the company, Collins employed more than 40 workers. Collins double bit and single bit axes came out of this factory.

Collins made the wise choice to hire Elisha K. Root, who was a mechanical engineering genius and later went on to work for Colt Firearms and serve as that company’s president. Root’s insight allowed the Collins Company to greatly improve the quality and manufacturing process, allowing them to make more and better axeheads, faster. Among the innovations he implemented was a system that made sure that all axes got the same heat treatment, and allowed for less time-consuming grinding.

In 1859, Scientific American reported that the Collins Company employed 350 people and produced 2000 tools daily – not monthly or yearly, but daily. By then, Collins had expanded and was also producing “adzes, picks, sledge-hammers, hoes, cane-knives, Spanish-machetes, and a whole host of other tools passing through the different processes from the rough-bars of iron and steel, until they were polished like glass, finished and packed ready for transporting to the sales office in New York” – so wrote Scientific American.

Collins tools – specifically, machetes – became highly-regarded and well-known throughout Central and South America. The Uruguayan writer Horacio Quiroga praised Collins machetes in his short stories. The author spent many years in the jungles of the Misiones region in modern-day Argentina. Not bad for a company from small-town Connecticut.

Even nowadays Sam Collins Day is a yearly celebration held in Canton, Connecticut, and the area where the factory and worker housing were located is known as Collinsville.

Unfortunately, the company suffered double-whammy blows in the 1950’s and 60’s. A severe flood in 1955 damaged part of the factory and the rail lines leading to it. The more serious problem was increased competition from mass-manufacturers of tools and the rise of the chainsaw that replaced axes in forestry and among builders. In 1966, after 140 years of operation, Collins Company closed its doors. Its South American operation was sold to Stanley Tool, and the domestic US operation, including the Collins name, was bought by Mann Edge Tool Co. of Lewiston, Pennsylvania. Finally, in 2004, Truper Herramientas bought the Collins brand and shifted manufacturing to Mexico. That’s the long and short of Collins axe history.

Are Collins axes any good?

This is a question that many people who aren’t “in the know” ask, as they hear great things about Collins axes but, when looking at reviews of the modern products, see something different and not as enthusiastic. The answer depends on the time period when the axe was made. Simply put:

Collins axes from before 1966 are great. They are high-quality tools made using years of experience and know-how.

Collins axes after 1966, when Mann Edge Tool Co. manufactured them, are good. While not at the same level of quality as “true” Collins axes, they are still tools made to a high standard in the USA.

Post-2004 Collins axes are made in Mexico and can be said to be “good enough”.

If you’re a regular axe user, you’ll want to invest in something more high quality. Council Tool axes are good choice, combining great US-made quality with surprising affordability.

For more occasional axe users, Collins axes are cheap and good enough, and are great for work that you wouldn’t want to spoil higher-quality, more expensive axes with. That includes stuff like chopping roots, splitting wood on the ground, and other “dirty” jobs.

Currently produced Collin’s axe Types

- Pulaski Axe

- Double Bit Axe

- Single Bit Axe

- Hatchet

- Splitting Maul

- Hunters Axe

- Half Hatchet

- Splitting Wedge

- Mattock

Brands Made by the Collins Company

- Dynamicus

- Homestead

- Old Timer

- Red Seal

- Commander

- Collins Bonded Axe

- Hercules

- Red Knight

- Fleetwood

- Collins Kromite or Choprite

- Rayo

- Luchador

- El Martillo

- Legitimus

Where are Collins Axes Made Today?

After 2004 Collins moved their axe manufacturing to Mexico after a series of split-offs and buy-outs, when Truper Herramientas finally purchased the brand. From this point, the quality of the axes did suffer however the price did also drop. I judge modern Collins Axes as good enough to be used for chopping roots or splitting wood, but I recommend getting a higher quality axe for felling trees.