Key parts of a chainsaw include the engine (gas or electric), chain, guide bar, chain tensioner, clutch, sprocket, carburetor, throttle, choke, starter, hand guard, rear handle, trigger, chain brake, chain catcher, oil reservoir, fuel tank, muffler, air filter, and spark plug. These components work together for efficient and safe operation.

Understanding how a chainsaw works is essential for beginner users, and that starts with a thorough explanation of the parts of a chainsaw. In this guide, I have compiled a quick summary of all the critical components so you can understand what is happening when you pick up your first chainsaw.

This doesn’t go into all the intricate machinery involved in creating these complex devices, but it is enough to compare options at your local hardware store and talk sense with their sales staff.

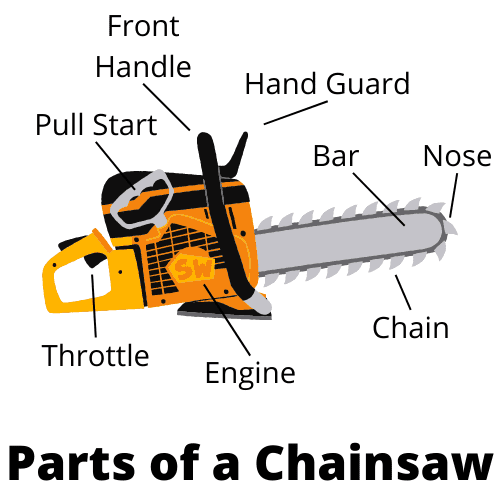

Let’s start off by looking at this illustration of a chainsaw and the main chainsaw parts:

Table of Contents

Bar

The bar, also known as the guide bar, is the piece of metal sticking out of the front of the chainsaw that the chain spins around. It keeps the chain in place and straight while cutting. The length of the bar is often used to describe the size of a chainsaw with a 20-inch bar being the largest industrial chainsaws available, going down to 10-inch bars for landscaping and gardening.

Chain

The chain is the main cutting instrument on a chainsaw (hence the name). It is wrapped around the bar and spins rapidly, driven by a gas or electric-powered engine. The chain is made up of sharp teeth that are a set distance apart – called the pitch. The width of the chain is called its gauge. Different brands of chainsaws use different designs and styles of chains.

Chains must be sharpened and replaced regularly to ensure the chainsaw performs at a high level.

Tensioner

The chain tensioner is used to tighten or loosen the chain so that it spins are the correct speed. If the chain is tensioned too tightly, it cannot spin fast enough. If the chain is too loose, it can fall off the bar. Setting the chain’s tension is an important first step before using your chainsaw.

Modern chainsaws often have automatic tensioners that reduce the maintenance the user needs to conduct.

Nose

The nose refers to the front of the chainsaw bar. You should always ensure you are cutting below the nose. Cutting at or above the nose can result in a kickback, which is extremely dangerous. A sprocket is installed on the nose to keep the chain in position.

Hand Guard

The hand guard is a crucial safety feature that protects your front hand from debris as wood chips start flying. The position of the hand guard also gives you better control over the chainsaw if it kicks back and moves up and towards you. You should never use a chainsaw that doesn’t have a suitable hand guard installed.

Regardless of the hand guard, I always recommend wearing safety gloves to add further protection.

Chain Catcher

The chain catcher is another safety feature often located underneath the bar as it connects with the engine. This is used to ‘catch’ the chain if it ever snaps to prevent it from striking the user. Never use a chainsaw that doesn’t have a sufficiently well-designed and maintained chain catcher.

Front Handle

The front handle is where you place your front handle, which holds up most of the weight of the chainsaw. This is placed immediately behind the hand guard, making it quite safe. The handles on a chainsaw will often have vibration-reducing grips to avoid stress on your hands and joints.

Engine

The engine is the main part of a chainsaw. In a gas-powered chainsaw, this combustion engine uses gasoline and air to burn and generate rotational movement that is transferred into the chain around the bar. In an electric chainsaw, this is an electric motor. This makes up most of the weight of a chainsaw, which is why electric chainsaws often weigh less than gas alternatives.

This engine size changes depending on the size of the chainsaw, with industrial chainsaws having gas engines up to 60 cc, while smaller options can be only 30 cc or less.

As part of the engine you will also find air filters, carburetors, and other mechanical components.

Fuel Tank / Battery

The fuel tank is used to store fuel in a gas engine. Having sufficient fuel available means you can keep cutting for extended periods without stopping to refuel. The fuel tank size determines how long you can work for but also increases the machine’s weight.

Electric chainsaws also have batteries that fulfil this same purpose. Batteries often last between 45 minutes and 1 hour, depending on the size of the chainsaw and the battery. I always recommend carrying secondary batteries so you can switch between them as they deplete and recharge.

Oil Reservoir

Chainsaws use bar oil to lubricate the metal components between the bar guide and the chain. This is not sealed, so you will lose bar during operation – this is called oil sling. Manufacturers generally make their oil reservoirs large enough to lose 1/2 of the oil in your reservoir for every 1 tank of gas, so you never run out of oil. But ensure you refill your oil reservoir every time you fill your gas tank.

I have put together a guide to chainsaw bar oil that you might be interested in.

Throttle

The throttle controls the chain’s rotation speed, effectively driving the cutting rate. In a gas chainsaw, this controls the amount of fuel injected into the engine. In an electric chainsaw, this controls the amperage from the battery.

You will also often find a throttle lock on the other side of the back handle. This is used to avoid accidental acceleration.

Pull Start

In gas chainsaws, the pull start is used to start the engine on a gas-powered chainsaw. These are also called recoil start handles. You will also find a choke control nearby that adjusts the fuel-air mixture during a pull start. Finally is a primer bulb used to prime the engine with gas before starting. Electric chainsaws don’t have chokes, primers, or pull starts.

Bumper Spikes

Bumper spikes are metal installed where the bar connects to the engine. This is used to rest your chainsaw against to keep the cutting edge away from the kickback zone. These are also known as bucking spikes.

Muffler

Mufflers are installed on gas-powered chainsaws to reduce their noise. This is important, especially in larger models that can be defeating. You should also wear hearing protection when using noisy machinery. Checking the muffler is an important first step before selecting a chainsaw and comparing the noise generation defined by the manufacturer.

That brings me to the end of this article explaining the different parts of a chainsaw. If you are looking for more in-depth knowledge, I would suggest reading through OSHA’s ANSI B175.1-1991 – Gasoline-Powered Chainsaw Safety Requirements, which may answer all your questions.